Case Story Krones Academy Asia

Krones AG has relied on Intelligent Cooling Solutions from Frigel for its new Krones Academy Asia facility.

Krones AG, industry leader in bottling & packaging machinery sector, has relied on Frigel for its new Krones Academy Asia facility.

The Krones Academies are knowledge centers where training on Krones products and technologies is available to customers. The Academy Asia is located in Bangkok and includes, among other equipment, a "Contiform" blow molding machine (BMM) and its HP air compressor unit, both of which require cooling for their operation.

Solution

The client's special needs led Frigel to suggest an "Ecodry system" solution that includes.

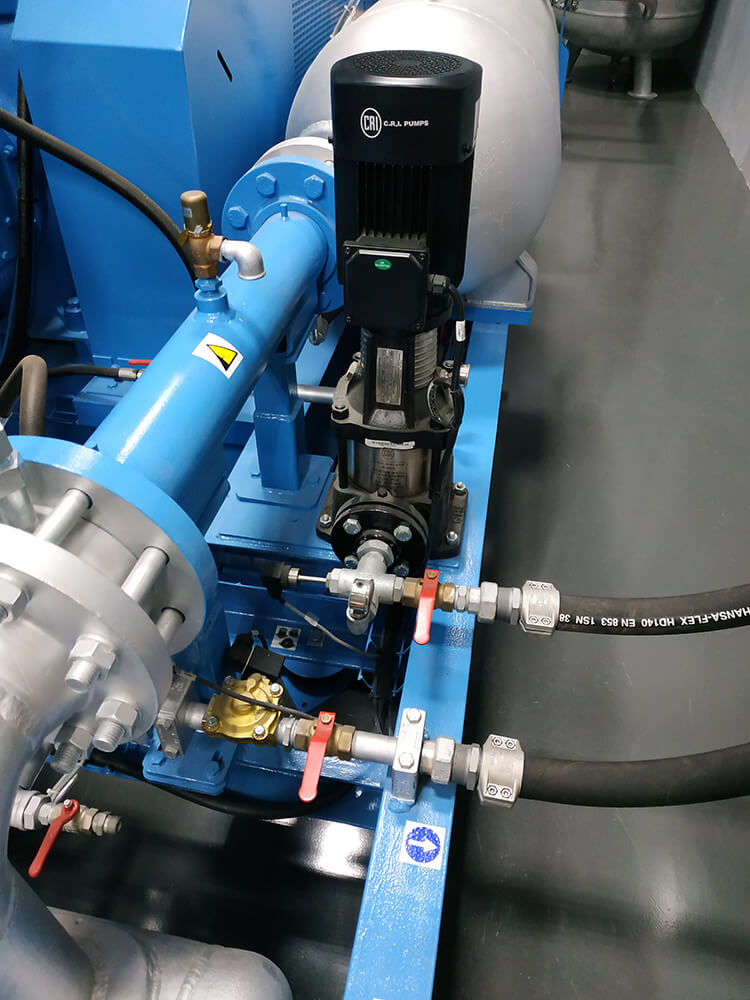

- A high performance mold cooling unit Microgel for Packaging for the Krones Contiform 308 H, conveniently installed right next to it. Microgel meets the needs perfectly, thanks to its super compact design and quiet operation. The unit includes a water-cooled chiller, accurate temperature controller and high flow booster pump. Being water -cooled, Microgel doesn’t exhaust hot air in the ambient. This configuration also minimizes the number of water pipelines required: the choice of an air-cooler chiller would have required a dedicated set of long insulated pipes, running from the 2nd floor roof to the Academy, at ground level.

- A flagship Frigel patented adiabatic cooler Ecodry – for the overall heat rejection to ambient of both loads, the Microgel and the high pressure air compressor simultaneously. Ecodry is a patented closed-loop adiabatic cooler capable of guaranteeing up to 95% of water and maintenance savings compared to a traditional evaporative cooling tower.

- A Frigel “3PR” remote control panel (PLC), installed inside the Academy and has been connected via Modbus cable to the Frigel equipment for the overall system management and supervision.

PET plastic processing applications are a well-known area of expertise for Frigel, which can provide a wide range of cooling solutions: from specially designed water-cooled side-machine chillers to the latest generation adiabatic coolers, from air- and water-cooled central chillers to mold dehumidifiers.

In this case, the need for cooling both at ambient and chilled temperatures, together with the configuration of the spaces and the specific needs of the customer, led Frigel's designers to use a typical "Ecodry system" solution.

The “Ecodry system” includes a Microgel (side-machine water-cooled chiller) and the flagship Frigel Ecodry (patented adiabatic cooler). The Microgel meets the needs perfectly, thanks to its super compact design and quiet operation, while the Ecodry can take care of the heat rejection of the Microgel and the air compressor simultaneously.

For more information

Contact us