Advantages

Practical and ready to install

-

Simplifies installation.

-

Facilitates the loading of chemicals.

-

Electronic level control.

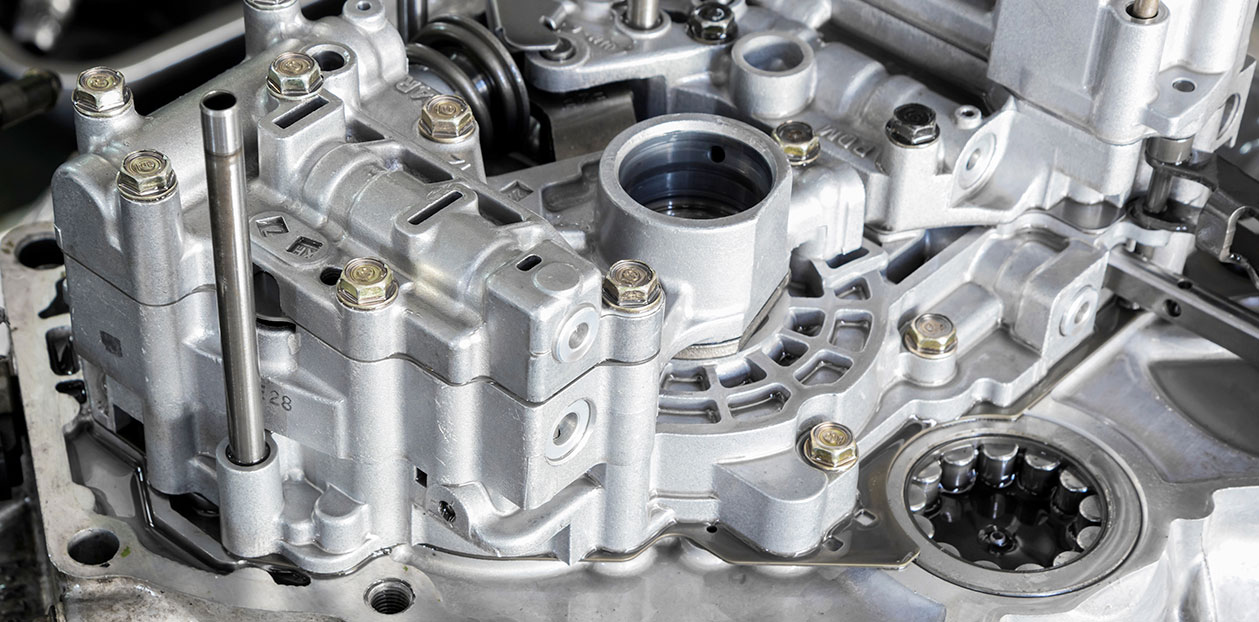

The storage tanks are made exclusively of stainless steel and are designed for coupling with the pumping groups, both for recirculation and process. They are made in various capacities and versions to meet the requirements of the various cooling systems and are connected to the control panel (3PR) for electronic level control.

Stainless steel tanks

Simplifies installation.

Facilitates the loading of chemicals.

Electronic level control.

Wide range of capacities from 1,000 to 5,000 liters (264 to 1,320 gallons).

Connections prepared for recirculation and process.

Electronic pressure transducers.

Inspectable and complete with a drain valve.

Process synchronized Cooling: innovation in the plastic industry

Process-synchronized Cooling. A paradigm shift in Food & Beverage.

Power

Power

Power

Metals

The most evolved free-cooling technology: customized solutions for data center

Process Cooling

Products that can help you.

Customized solutions for your business

*required fields

Customized solutions for your business

Rotate the device to better view the site

Link copied to the clipboard