Advantages

Increased productivity for Injection Molding

-

Production increase of up to 33% thanks to cycle time reduction

-

25% cycle time reduction compared to standard TCU

-

Intelligent energy consumption

-

High energy savings with automatic free-cooling (for “Ecodry” version)

-

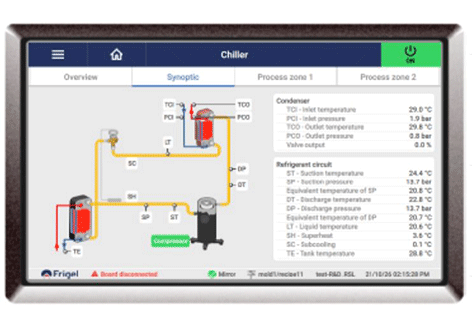

Ready to remote interface via MiND™ supervision system

-

Significant energy savings

-

Control providing real-time temperature, flow, and pressure readings, seamless integration with your processing machines