Organic Rankine Cycle (ORC)

FLEXIBILITY, SIMPLICITY OF SOLUTIONS, SUSTAINABILITY

Organic Rankine Cycle (ORC)

Optimized cooling solution and energy saving for a faster payback time. ORC is one of the most used solution to generate electricity from low temperature heat sources.

Organic Rankine Cycle (ORC) is a power generating process which uses refrigerant instead of water/steam. It is running on much lower temperatures than the standard water/steam cycle, typically around 120-180°C.

In few words, ORC is a power generating process producing electrical energy from heat at temperatures which are not high enough to generate steam out of water but still high enough to generate steam out of a refrigerant.

Waste heat recovery

Waste heat recovery is one of the most important development fields for the organic Rankine Cycle (ORC). It can be applied to heat and power plants (for example a small scale cogeneration plant on a domestic water heater), or to industrial and farming processes such as organic product fermentation, hot exhausts from ovens or furnaces (e.g. lime and cement kilns), flue-gas condensation, exhaust gases from vehicles, intercooling of a compressor, condenser of a power cycle, etc.

Biomass power plant

Biomass is available all over the world and can be used for the production of electricity on small to medium size scaled power plants.

The problem of high specific investment costs for machinery, such as steam boilers, are overcome due to the low working pressures in ORC power plants.

Another advantage is the long operational life of the machine due to the characteristics of the working fluid, that unlike steam, is non-eroding and non-corroding for valve seat tubing and turbine blades.

The ORC process also helps to overcome the relatively small amount of input fuel available in many regions because an efficient ORC power plant is possible for smaller sized plants.

Geothermal plants

Geothermic heat sources vary in temperature from 50 to 350 °C. The ORC is therefore perfectly adapted for this kind of application.

However, it is important to keep in mind that, for low-temperature geothermal sources (typically less than 100°C), the efficiency is very low and depends strongly on heat sink temperature (defined by the ambient temperature).

Main Opportunities:

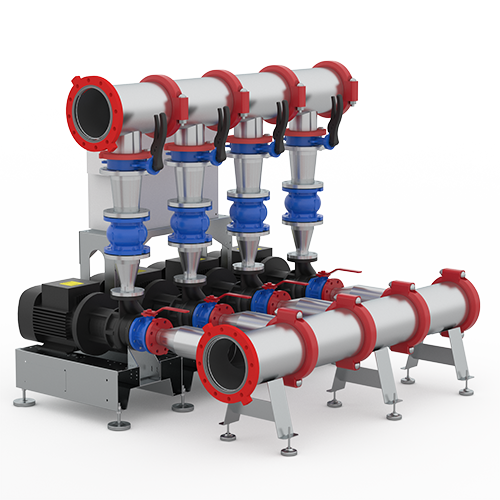

- ORC cycles required condenser cooling water at temperatures ranging from 25 to 35°C.

- Dry coolers LDK

- Adiabatic fluid coolers ECODRY

Our solutions

Discover the complete range

The most efficient solutions on the market for every process need.