Advantages

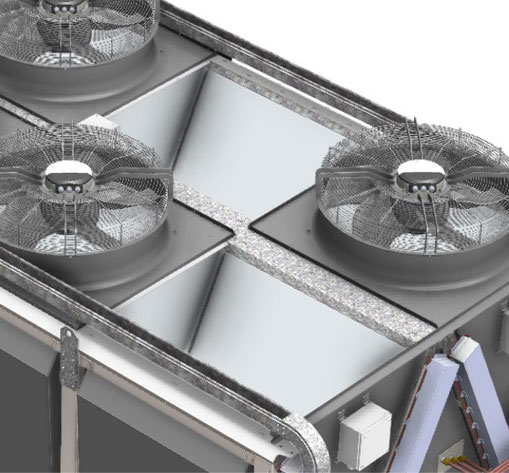

A fluid cooler with better performance

-

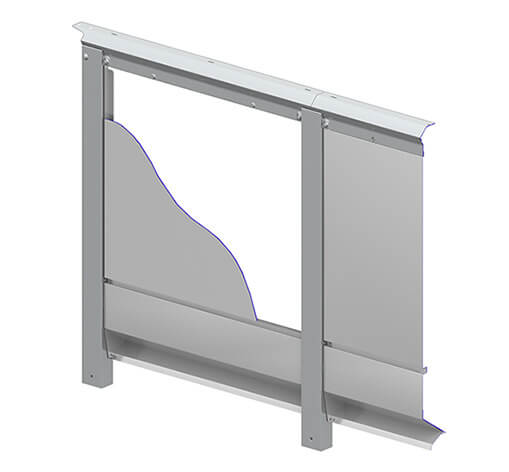

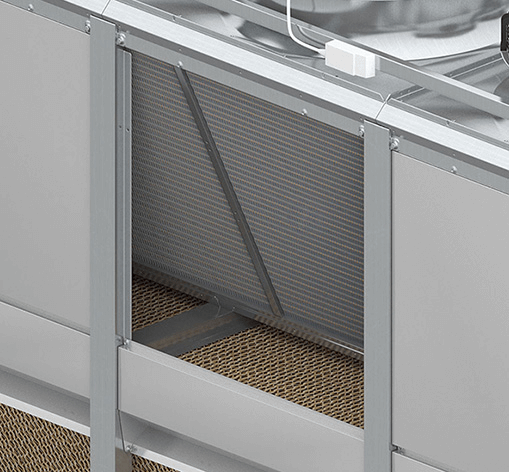

Compact design: Improved capacity/footprint ratio with 40% lower footprint required between the units

-

Total modularity, high reliability: Easy to expand at anytime to meet growing needs

-

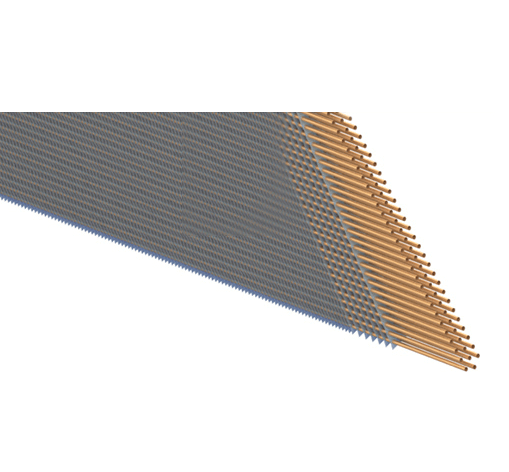

Glycol-Free operation: 100% reliability in sever weather conditions down to -30°C (-22 ˚F)

-

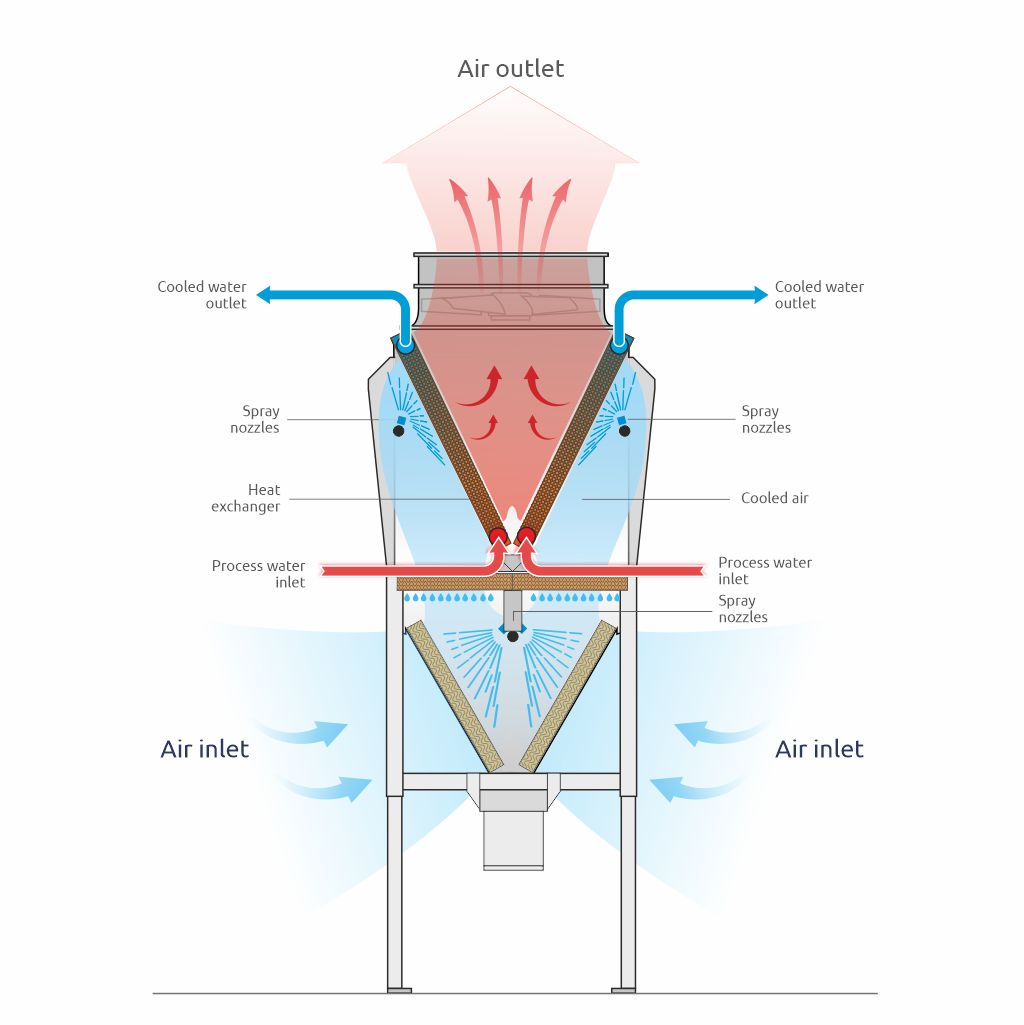

Self-draining configuration optimizes performance with glycol-free applications in freezing climates

-

Minimal ongoing chemical treatment required