Fair and events

Discover the next events' calendar

Magazine

Every news about Frigel Group

Your Business

Performance and sustainability without compromise

Cooling systems have a decisive influence on your business and the environment around us.

Improve your competitiveness and respect the environment with Intelligent Process Cooling Systems.

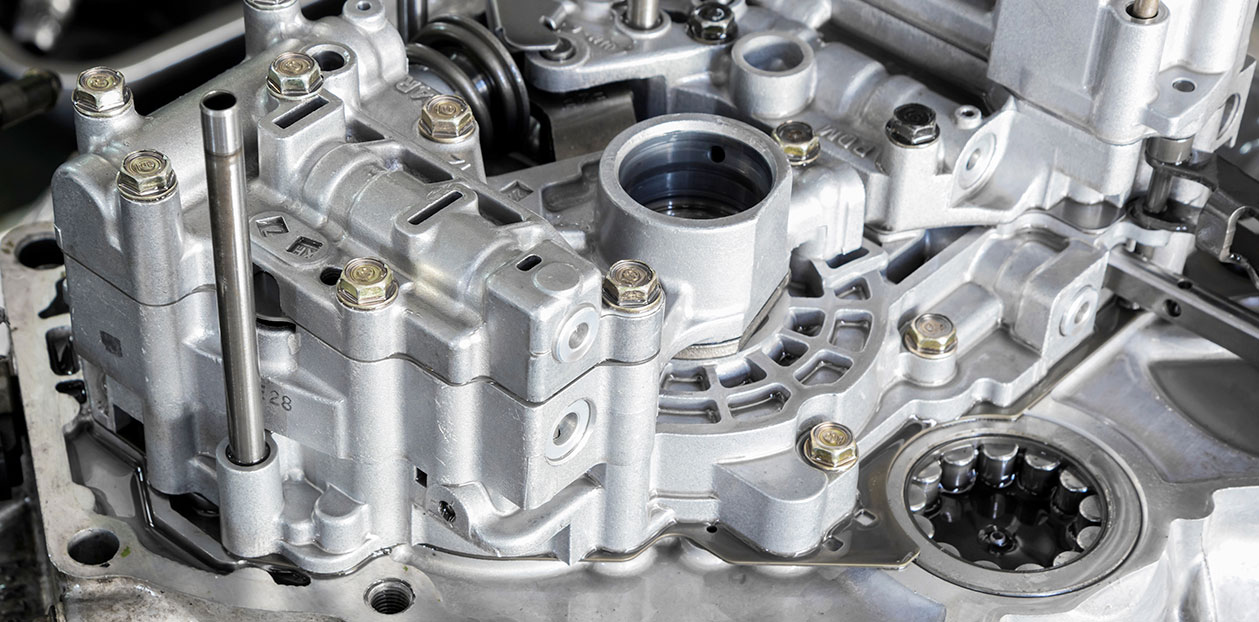

Plastic & Rubber

Process synchronized Cooling: innovation in the plastic industry

- Reduction of cooling times.

- Better quality of molded components.

- Perfect repeatability and reduced costs and environmental impact.

Food & Beverage

Process-synchronized Cooling. A paradigm shift in Food & Beverage.

- Significant increase in productivity.

- Total connectivity and automation.

- Perfect repeatability and reduced costs and environmental impact.

- Complete absence of ammonia.

Process Cooling

Metals

- Reduction of cycle times.

- Reduction of operating costs with lower energy consumption, water and maintenance.

Gas Turbine Air cooling

Power

Biogas

Power

Power Grid

Power

Data Centers

The most evolved free-cooling technology: customized solutions for data center

Organic Rankine Cycle (ORC)

Air Compressor cooling

Process Cooling

Our Philosophy

Constant search for increasingly efficient and sustainable engineering solutions

Sustainability is the guiding principle for our ability to imagine and innovate.

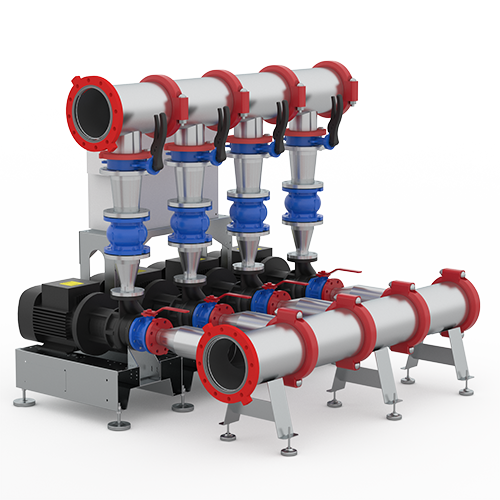

Our solutions

Discover the complete range

The most efficient solutions on the market for every process need.

Frigel Group

Process Focused, Technology Powered

Frigel is much more than a manufacturer of cooling and temperature control systems.