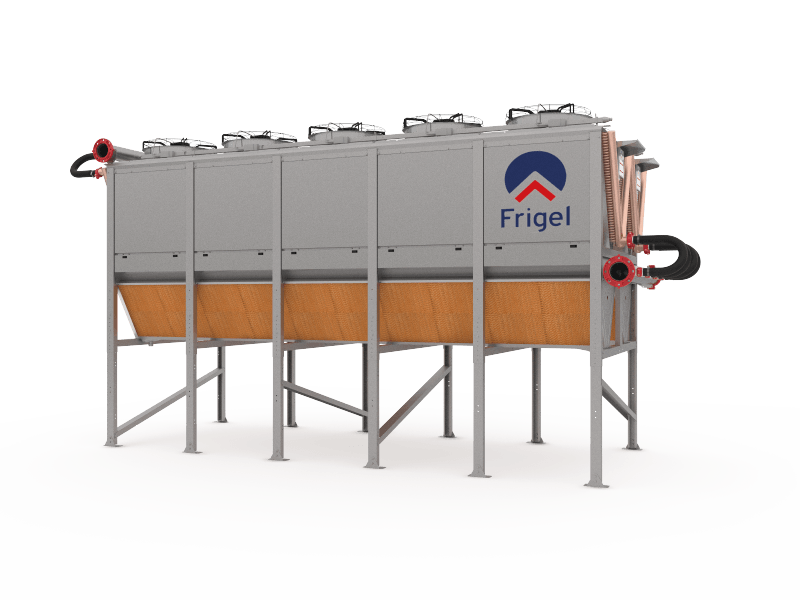

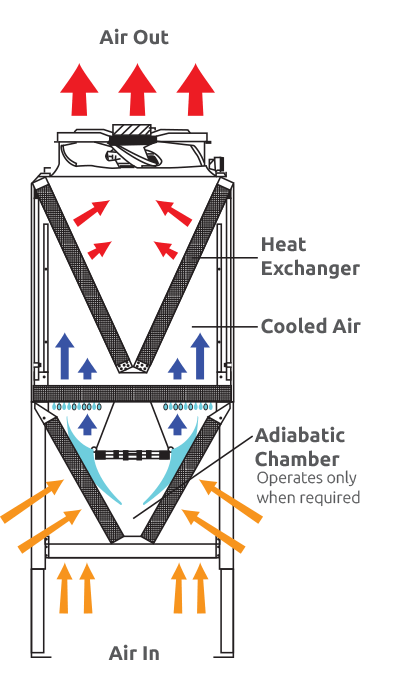

Advantages of Adiabatic Cooler

A fluid cooler with better performance

-

Guaranteed operation with minimum water consumption and maintenance even in extreme climatic conditions, up to 50 °C (122 ˚F) ambient air temperature.

-

Safe winter operation without glycol down to an ambient temperature of -40 °C (-40 ˚F).

-

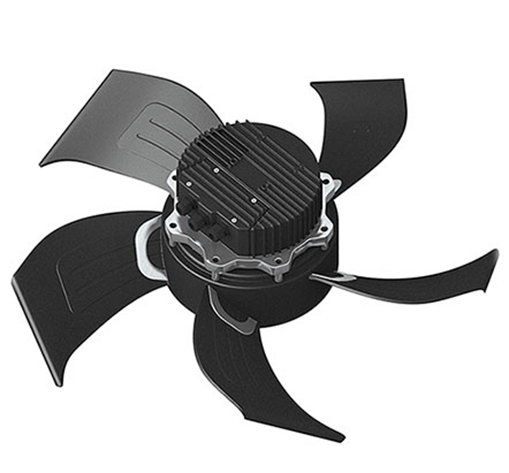

High energy savings of fans in partial load operation.

-

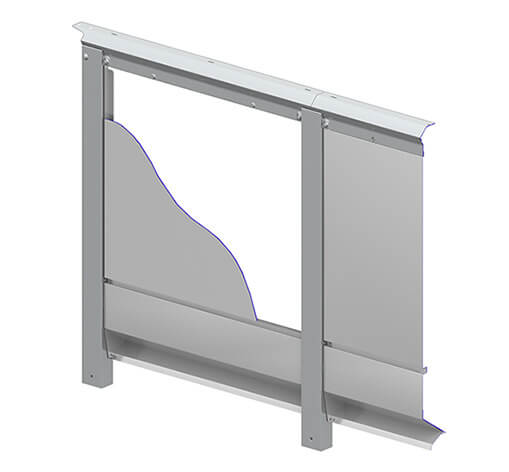

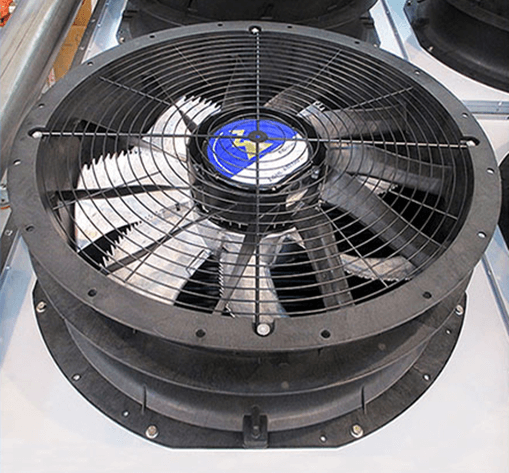

Compact installation with minimal floor space required between modules.

-

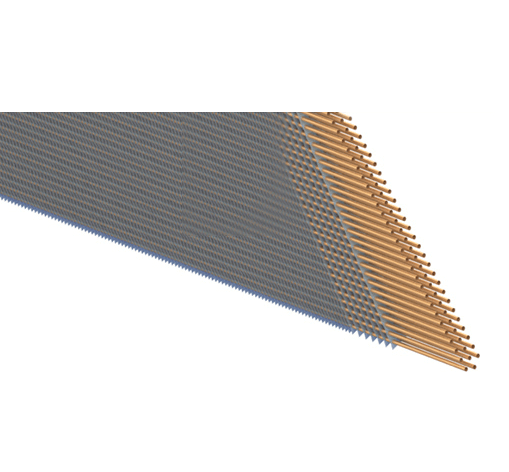

High reliability with electrical redundancy and built with 100% non-ferrous materials.