A paradigm shift in Food & Beverage

Ecodry System 4.0 Process-Synchronized Cooling

Cooling has a big impact on cost of each process.

An innovative integrated cooling solution aimed to water savings, energy savings and a minimal footprint impact, helping the cooling processes for: juices, isotonic and carbonated drinks, tea, beer, cheese, chocolate, bakeries, fruit, vegetables, etc.

Performance and Sustainability

Reduced carbon footprint up to 50% less

Unbeatable efficiency, free-cooling and heat recovery opportunities.

How does Ecodry System 4.0 work?

Integrated cooling solution for Beverage Industry

From non-alcoholic beverages to beer, from processing to bottling, this approach meets all the cooling needs required by the industry, with performance improvements, unbeatable savings on operating costs and an exceptional reduction in environmental impact.

Microgel and Multistage

Process-Synchronized Refrigeration Units

A revolutionary approach that does not include a refrigeration system for the entire production plant, but compact cooling units dedicated to each processing line.

Each unit is designed for a specific application, uses low GWP refrigerant gas and can have single-stage refrigeration circuits (Microgel) or multistage cascade circuits (MultiStage) with inverter-driven screw compressors.

Digitally synchronized with the processing line (from which it is managed automatically), each unit allows searching and recording, for each product, the best cooling parameters to maximize productivity. Furthermore, water chillers can be water cooled and used as “heat pumps” for energy recovery.

Ecodry

Central Adiabatic Cooling System

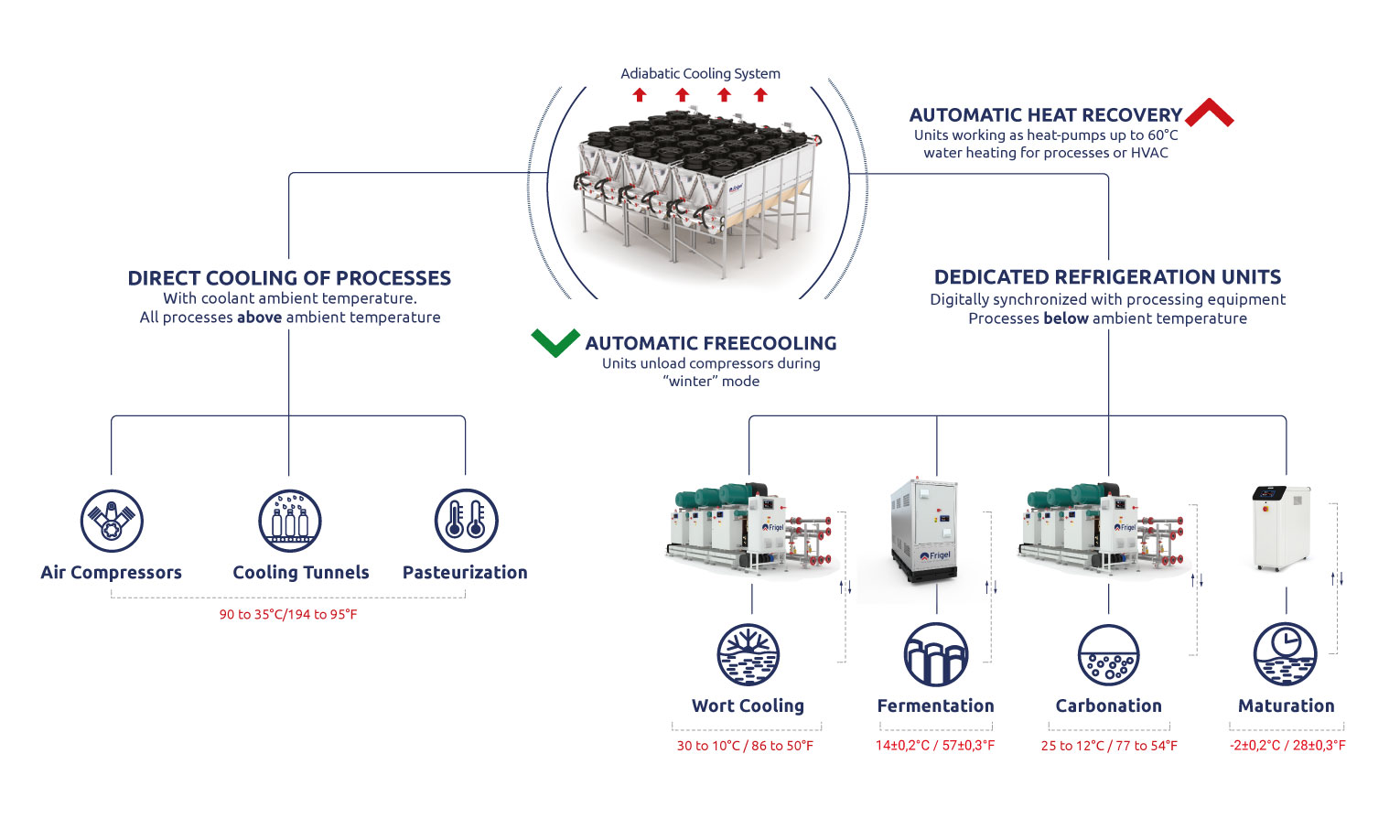

The Ecodry System is completed by an adiabatic cooling central positioned outside, to expel the heat deriving from the processes.

This modular system - an alternative to evaporative towers - consists of closed-circuit adiabatic coolers that can keep the cooling temperature even lower than the ambient temperature.

Furthermore, this central system can provide direct cooling to all other users that require water at a temperature higher than the ambient temperature, such as pasteurizers, cooling tunnels, air compressors, water-cooled chillers, etc.

Ecodry System 4.0 for Food & Beverage

Discover the new cooling technologies for every field of application.

Carbonated Soft Drinks

Cooling system synchronized with the carbonated beverage production process.

Learn more

Soft Drinks

Cooling system synchronized with the process for the production of juices, isotonic drinks and tea.

Learn more

Beer

Cooling system synchronized with the brewing process.

Learn more

Food

Cooling solutions for Dairy Products, Chocolate & Sweets, Pasta, Processed Fruit & Vegetables, etc.

Learn more